Reference : SIA-SIA155-64-96V-29KW

€11,998.80 tax. incl.

€9,999.00

tax. excl.

Manufacturer Part Number (MPN) : SIA155-64 | Brand: SiAECOSYS

The SIA155-64 is a permanent magnet synchronous motor (PMSM) with an IPM (interior permanent magnet) topology, designed for high power density mid-drive architectures in electric mobility platforms. Its rated output (12 kW) and peak capability (29 kW) target compact traction systems where torque dynamics matter: lightweight e-motorcycles, dirt bikes, go-karts and small electrified vehicles.

The hairpin winding technology supports an efficiency- and thermal-oriented stator design, consistent with high-current operation. System integration is typically based on a FOC (field-oriented control) inverter, using an encoder feedback and a PWM command interface on the control side (throttle/torque request depending on the inverter architecture). The integrated KTY84/130 temperature sensor enables a structured thermal derating and protection strategy within the power electronics.

Designation: Traction PMSM (IPM) mid-drive motor with hairpin winding, 12 kW rated / 29 kW peak, 96 V, spline shaft, encoder, IP67, surface air cooling.

Key benefits

- PMSM (IPM) topology: suitable for FOC drives, enabling accurate torque and speed control for traction.

- Hairpin winding: design approach optimized for power density and winding thermal conduction.

- 96 V voltage window: facilitates integration on high-performance low-voltage battery architectures (recommended range 86–113 V).

- 85 N·m peak torque / 7500 rpm max speed: balanced torque-speed envelope for primary transmission (chain, belt, gearbox).

- IP67 + surface air cooling: suitable for exposed environments, provided the mechanical integration and airflow are consistent.

- KTY84/130 temperature sensor: robust basis for derating, diagnostics and stator thermal protection.

- Spline shaft: mechanical interface suited to traction constraints (impulse torque and cycling).

Technical specifications

| Technology | PMSM (IPM) |

| Use / type | Mid-drive traction motor |

| Rated operating voltage | 96 V |

| Recommended voltage range | 86 to 113 V |

| Recommended min / max nominal voltage | 60 V / 120 V |

| Rated power | 12,000 W |

| Peak power | 29,000 W |

| Recommended rated current | 125 A (continuous) |

| Recommended peak current | 302 A (burst) |

| Rated torque | 20.0 N·m |

| Peak torque | 85.0 N·m |

| Rated speed | 4000 rpm |

| Max speed | 7500 rpm |

| Number of pole pairs | 4 |

| Winding configuration | Star (Y) |

| Cogging torque | 1.4 N·m |

| Radial runout | ≤ 0.035 mm |

| Axial play | ≤ 0.3 mm |

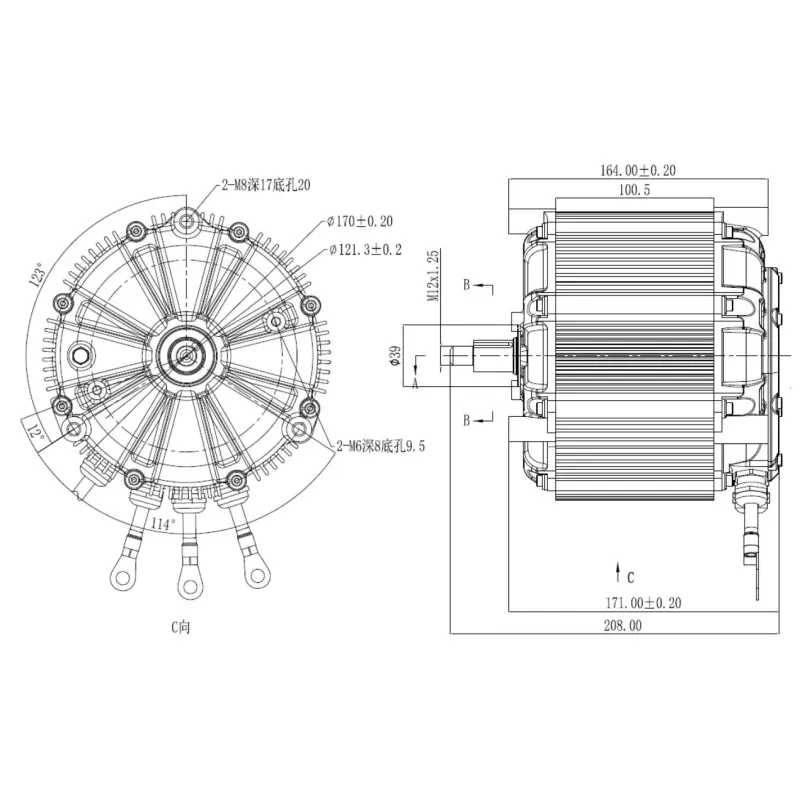

| Active geometry | Core diameter 155 mm; magnet height 64 mm |

| Shaft | Spline |

| Cooling | Surface air cooling (convection/air over surface) |

| Temperature sensor | KTY84/130 |

| Operating temperature | 70 to 120 °C (peak 150 °C) |

| Ingress protection | IP67 |

| Power connection | 13 mm² phase conductors (without insulation); M8 lugs |

| Phase cable length | Yellow 230 ±20 mm; Blue 280 ±20 mm; Green 330 ±20 mm |

| Phase identification | U=Blue; V=Green; W=Yellow |

| Mass | 12.8 kg |

Typical applications

- E-motorcycle (light road / enduro) with primary transmission and an encoder-based FOC inverter.

- Electric dirt bike: dynamic use with high transient loads (burst current).

- Electric go-kart / buggy focused on performance (repeated acceleration, wide speed variation).

- Small electrified vehicles (light platforms) in a ~96 V architecture with tight packaging and mass constraints.

Recommended integration

- System compatibility (electrical/control)

- Select an inverter supporting PMSM IPM in FOC, capable of 125 A continuous and handling peaks consistent with 302 A burst, according to the mission profile and thermal design.

- Use the encoder feedback for commutation and the speed/torque control loop; implement clean signal routing and sensor supply according to the inverter architecture.

- Integrate the KTY84/130 sensor into the protection logic: warning thresholds, torque reduction, shutdown on overtemperature.

- Parameterization and configuration

- Calibrate voltage/current limits in line with the 86–113 V range and the rated/peak targets; set burst current according to allowable duration and repetition at system level.

- Define rotation direction and phase mapping (U/V/W) during commissioning, then freeze the configuration (wiring documentation + production control).

- Mechanical layout and ventilation

- Design the mechanical interface around the spline shaft with strict control of alignment and loads (transmission, chain/belt tension, vibration).

- With surface air cooling, place the motor in a ventilated area, leverage heat exchange surfaces, and implement derating in hot ambient or low airflow conditions.

- Cable sizing and routing

- Size the phase links from the 13 mm² conductors and M8 lugs; minimize lengths, avoid loops, and secure the cable exits mechanically (anti-vibration/strain relief).

- Electrical protections and safety chain

- Structure the DC chain: DC bus fuse(s), main contactor, precharge, emergency stop, and a cut-off strategy compatible with traction/regeneration (depending on the inverter).

- Implement fault supervision: overcurrent, overtemperature, encoder loss, DC bus over/undervoltage, speed/torque inconsistencies.

- EMC, diagnostics and maintenance

- Physically separate power and signals, control return paths/grounds, and protect/filter encoder and PWM inputs according to inverter recommendations.

- Plan for maintenance access: connector inspection, lug torque checks, temperature monitoring, fault event tracking and inverter parameter traceability.

Compatibles accessories

The accessories below showcase a selection of components commonly integrated and/or recommended with SiAECOSYS - SIA155-64 - 96V PMSM motor to optimize installation, compatibility, and overall performance.

| Category | Accessories | |

|---|---|---|

| LEAD-ACID BATTERIES |

Operating conditions

- Power and torque levels require a properly sized battery + inverter + cabling + cooling system for the target currents (up to 125 A continuous and 302 A burst recommended).

- Thermal performance depends directly on air cooling and the environment (ambient temperature, enclosure, airflow velocity).

- IP67 must be evaluated at the integrated system level: effective sealing depends on the mechanical architecture, cable exits and interface management.

- Final compliance (EMC, electrical safety, environmental robustness) results from the complete integration and remains the integrator’s responsibility.

The information above is provided for technical and indicative purposes to support design and integration work.

Performance, robustness and compliance depend on real operating conditions, inverter parameterization, and the electrical/mechanical/thermal integration of the complete system. Final validation (functional, thermal, EMC and safety) is required before commissioning.

FAQs and Articles

Find below our product FAQ: quick answers to the most frequently asked questions (installation, compatibility, use, maintenance, warranties). To go further, also check out our dedicated articles: practical guides, expert advice, and best practices.

| Category | FAQ / Article(s) | |

|---|---|---|

| FAQ : ELECTRIC MOTORS | ||

| FAQ : ELECTRIC CONVERSION KITS |

Technical documentation

EVEA - SIA155-64-96V-29KW

EVEA Distribution – Datasheet

Generating PDF, please wait…

Zapi - ACE1 NG - datasheet

Datasheet for the COMBI ACE1 / ACE1 NG inverter, suitable for controlling multiple motor types (IM, SPM, IPM, SRM, SRPM) in battery-powered electric and hybrid vehicles, typically in the 4–8 kW range. Typical applications include stackers, order pickers, aerial lift platforms, reach trucks, and counterbalance trucks up to 2 t.

Datasheet

PDF from Google Drive

Other Information

- ean13

- 8468495329445

- Rating

- 4.2 / 5

- Review

- 5

- See all reviews

- Write a review